VIJAY WINDOW PATCHER MACHINE

A HIGH SPEED CARTON WINDOW PATCHING MACHINE WITH ADVANCED FEATURE & SERVO DRIVEN APPLICATION.

Feeder

Friction feeder equipped with vibrating motor helps in free flow of cartons from the pile. This feeder offers highest flexibility with regard to any blank shapes, suitable for both card board and corrugated material.

Vacuum feeding belt system.

Servo driven feeder

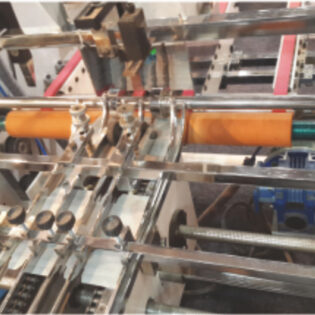

POSITIONING ROLLER & CHAIN STATION

This roller maintains the gape between the cartons uniformly even at higher speed. It coordinates free flow of cartons without wastage between the feeder and squaring chain station. This cartons move uniformly maintaining the accurate gape in between. It also positions and square the cartons accordingly.

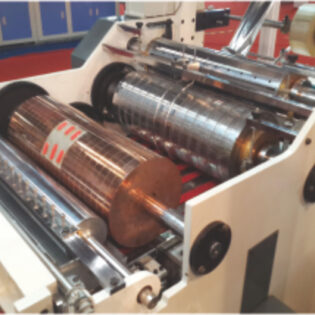

GLUING & SUCTION CYLINDER

Sliding of glue unit ensures easy removal of adhesive and cleaning process is less time consuming. Suction belts holds the carton firmly for accurate synchronization of glue impression and film/linner material on the carton. Rotary cutter cuts the material & transfers through vacuum transfer cylinder.

COLLECTING STATION

Easy accessible delivery belts ensures stream delivery which also counts and batches the cartons as desired.

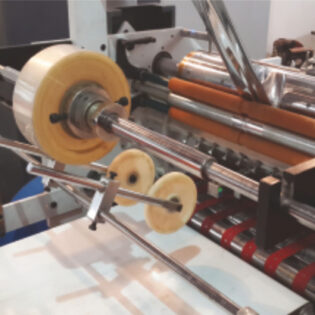

TENSION CONTROLLER

Automatic controller with braking controls the tension of reel, ensures smooth unwind of reel at high speed.

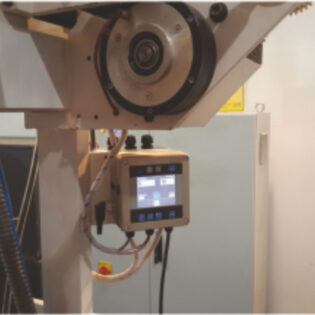

OPERATING STATION

Touch screen operating panel is user friendly and helps in easy operation of the machine.

TECHNICAL SPECIFICATION |

|||

Blank Length |

Minimum |

Maximum |

|

100 mm |

550 mm |

||

Blank Width |

90 mm |

550 mm |

|

| Window Film Length | 40 mm |

450 mm |

|

| Window Film Width | 30 mm |

400 mm |

|

| Liner Width | 60 mm |

250 mm |

|

| Film Thickness | 0.05 mm |

0.3 mm |

|

MATERIAL CALIPER (Paper & Cardboard) |

220 g/m2 to 600 g/m2 |

||

| Power Required | Max. 15KW |

||

| Dimension of the Machine | 5 mtr x 1.3 mtr width |

||

| Foil/Liner Real Diameter Inner/Outer | Inner ------ 76 mm Outer ----- 500 mm |

||

OUTPUT LINER STATION |

|||

| Blank Length Below 370 mm | 12000 Pcs/Hour |

||

| Blank Length Above 370 mm | 6000 Pcs/Hour | ||

OUTPUT WINDOW PATCHING |

|||

| Blank Length Below 370 mm | 15000 Pcs/Hour | ||

| Blank Length Above 370 mm | 7500 Pcs/Hour | ||